Project support boosts global energy management scheme

Nestlé helped to reach net zero goal by 2050

As part of Nestlé’s commitment to reducing greenhouse gas emissions, Endress+Hauser was engaged to deliver a package of support for energy monitoring in over 40 countries. The new systems in place give Nestlé better visibility over their energy usage, with the data available remotely and in real-time. They have eliminated the need for data input and manual calculations, improving ease of use and efficiency across the company’s sites.

The Benefits

-

Project support to meet environmental goals

-

Better visibility of energy consumption with remote access to data

-

No need for manual calculations

-

Standardised approach improves ease of use and efficiency across

sites -

Tamper-free data storage

The challenge

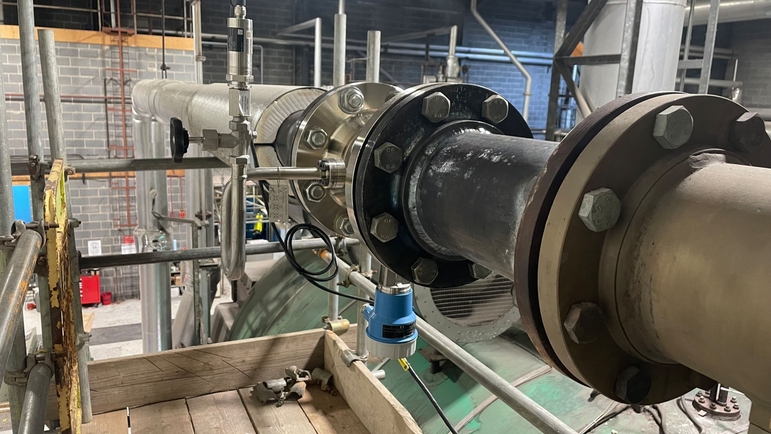

Nestlé required tools that would complement their self developed energy system to deliver global visibility on energy consumption down to production line level. At Nestlé’s site in York in the UK, which produces iconic confectionery brands such as KitKat, Polo and Aero, engineers wanted better visibility of the boiler house in particular. “We couldn’t see how much energy each boiler was using or what losses we were seeing in the boiler house,” explains Engineering Technician James Stevenson.

The solution

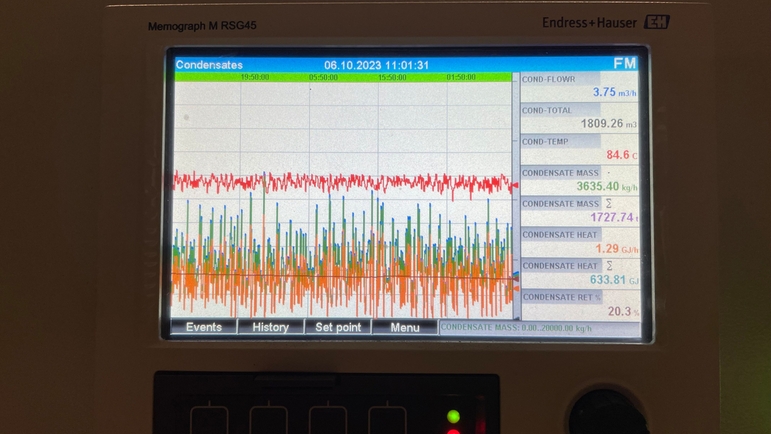

Endress+Hauser worked with Nestlé to develop a project execution plan for the initiative incorporating metering and connectivity solutions. As a result, more than 300 new instruments were sized, selected and delivered to Nestlé’s UK sites. Crucially, the new meters were connected to an advanced data manager, the Memograph M RSG45, which not only displays and stores process values for monitoring and analysis, but also calculates energy variables.

Unlocking valuable data

Rather than just supplying instrumentation, the idea was to give Nestlé valuable insights into their energy consumption data and support them with reporting and dashboarding of utility data and energy related KPIs. “Previously we weren’t using the full capabilities of our instrumentation and mainly used it for rough data and billing,” says James Stevenson. “But now we’re able to delve down into the efficiencies of the boiler house.”

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |